Engineering

Design capabilities are supported with mechanical engineers with multiple years of experience in manufacturing. We utilize Solidworks for 3D modeling capabilities. Please contact us for your design and development requirements.

Forging

Capabilities include hot forged processes such as upset forging and drop hammer forging. We can design to your specification, create the necessary tooling and manufacture high strength, high quality forgings for your design applications.

Welding

Mig, tig, fusion and robotic welding capabilities allow us to offer a broad range of weldments.

Casting

Multiple casting processes are available such as sand casting, investment casting, die casting and mold casting from a variety of raw material inputs including alloys, steel, aluminum, grey iron and ductile iron.

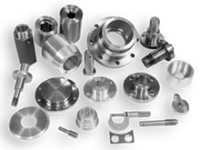

Machining

Our capabilities include cylindrical grinding, turning, milling, thread rolling, tapping, broaching, drilling, hobbing & many other processes to fit your needs.

Heat Treating

Our heat treating is done within controlled atmosphere furnaces and include quenching, tempering, normalizing annealing, carbonization, nitriding and induction case hardening.

Finishing

To complete the manufacturing process we are capable of finishing products by paint, powder coat, E-coat, zinc plate, chrome, oxidate, dacromet or geomet as well as any other special finishing you may require.

Quality

Our philosophy is you can only expect what you inspect. We are dedicated to checking product specifications during the manufacturing process and before products are shipped and delivered.

Of distribution and warehousing experience for manufactured custom OEM components for multiple leading original equipment manufacturing companies, Buchanan Global, Inc is dedicated to designing, developing, importing and distributing quality products at the best value possible.

Our background and expertise in engineering provides exceptional design and development capabilities. We utilize Solidworks software that allows us to model out each and every product we supply. Buchanan Global, Inc also employs an engineer with a masters degree in metallurgical sciences making us industry experts in material analysis and recommendation.

Other services than warehousing and distribution include inventory control, contract consignment, sourcing, quality control and inspection. We stock inventory according to our customer demands and utilize information available to us such as annual usage, foreasting, blanket orders, etc. As parts are sourced to our manufacturing partners, quality control is our strength. Control plans and manufacturing processes are put in place and then all parts are inspected according to those plans and processes to insure we supply repeatable quality parts.